Trends and Innovations

Corrugated boxes have long been a staple in the packaging industry, but did you know they’re also at the forefront of packaging innovation? As businesses and consumers alike prioritize sustainability, durability, and customization, corrugated boxes are evolving to meet these demands. Let’s uncover the latest trends and innovations shaping the future of corrugated packaging.

The Evolution of Corrugated Boxes

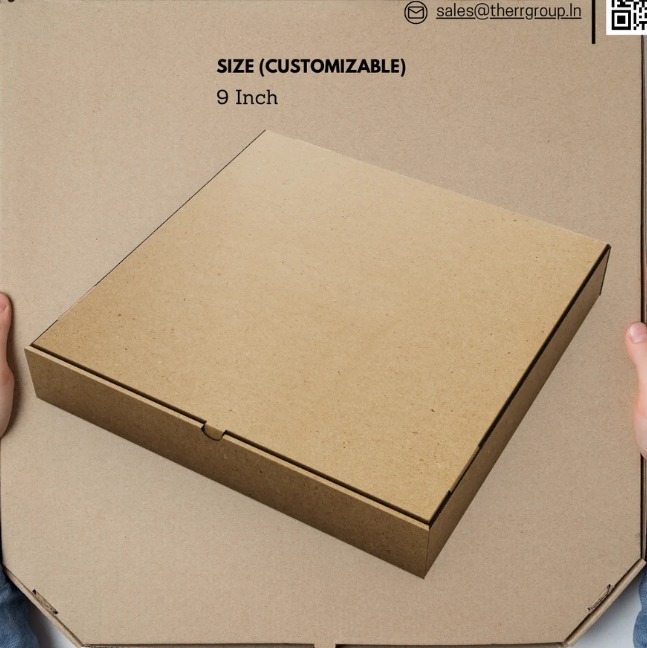

While traditional corrugated boxes are known for their sturdy, fluted design, recent advancements have introduced enhanced materials and manufacturing techniques. Today’s corrugated boxes are not just stronger but also lighter and more environmentally friendly than ever before.

Trends in Corrugated Box Design

- Eco-Friendly Solutions: The shift toward sustainable packaging has led to the development of boxes made from 100% recycled materials. Some manufacturers are also exploring biodegradable coatings and water-based adhesives.

- Smart Packaging: Integrating QR codes and RFID tags into corrugated boxes allows businesses to improve supply chain tracking and offer interactive experiences for consumers.

- Enhanced Printing Technologies: High-quality digital and flexographic printing techniques enable vibrant, detailed designs that elevate brand presence on the shelf.

- Modular Designs: Corrugated boxes are increasingly being designed for easy assembly and reuse, reducing waste and improving cost-efficiency.

The Role of Corrugated Boxes in E-Commerce

The boom in online shopping has underscored the importance of protective yet lightweight packaging. Corrugated boxes are tailored to meet these requirements, offering:

- Custom Inserts: For securing products of varying shapes and sizes.

- Tear-Resistant Designs: Ensuring products arrive in pristine condition.

- Minimalistic Aesthetics: Appealing to eco-conscious consumers who value simplicity and recyclability.

Innovations in Corrugated Box Manufacturing

- 3D Printing: Prototyping custom designs using 3D printing speeds up production and reduces material waste.

- Nanotechnology: Adding nanomaterials to improve strength and moisture resistance without increasing weight.

- Automation: Robotic systems streamline the cutting, folding, and printing processes, enabling faster production and consistent quality.

Benefits Beyond Packaging

Corrugated boxes aren’t just for shipping – they’re finding new applications in unexpected areas:

- Furniture: Modular furniture made from corrugated materials is lightweight, durable, and sustainable.

- Creative Art Projects: Artists and DIY enthusiasts are using corrugated sheets to create sculptures, models, and other crafts.

- Temporary Housing: Innovative designs have repurposed corrugated boxes into shelters for disaster relief scenarios.

Future Outlook for Corrugated Boxes

As industries embrace the circular economy, corrugated boxes will play a pivotal role in reducing packaging waste. The integration of advanced materials and smart technologies ensures that they remain a versatile and forward-thinking solution.

Conclusion

Corrugated boxes have transcended their original purpose to become a symbol of sustainability and innovation in the packaging world. Whether you’re a business seeking modern packaging solutions or a consumer looking for eco-friendly options, corrugated boxes continue to deliver unmatched value. Stay tuned as these humble boxes redefine the boundaries of what’s possible in packaging.